Introduction about Horizontal Cladding Machine

A Horizontal Cladding Machine is a specialized welding system designed for surface enhancement and repair of metal components. It is widely used in industries that require hardfacing or corrosion-resistant layers over existing materials. Cladding involves bonding a layer of superior metal to a substrate, improving durability, resistance to wear, and extending the service life of components.

Horizontal cladding machines automate this process, ensuring precision and consistency. Whether you’re working in the oil & gas industry, power generation, mining, or heavy engineering, this machine offers a cost-effective solution to restore and reinforce worn-out equipment. These machines are compatible with multiple welding technologies like SAW, GTAW, and PTA.

Features:

– Precision Cladding: Ensures accurate metal deposition for uniform coverage.

– Horizontal Bed Design: Suitable for large cylindrical or complex components.

– Multi-Welding Compatibility: Works with PTA, MIG/MAG, and TIG welding.

– Programmable Controls: CNC-based interface for automation and repeatability.

– Heavy-Duty Construction: Handles large components with ease.

– Safety Systems: Integrated sensors for overheating, arc protection, and emergency stops.

Applications:

– Oil & Gas Sector: Cladding of drill tools, valves, and pipelines.

– Power Plants: Surface restoration of turbine parts and rotors.

– Mining & Earthmoving: Repairing of wear parts like shafts and crusher rolls.

– Marine Industry: Corrosion protection for propellers and shafts.

– Steel & Cement Plants: Refurbishment of rollers, liners, and wear plates.

Technical Parameters:

| Type | 12-meter horizontal cladding machine 4 heads |

| Model No | HCS-2T-2W-2H |

| Process | Pulsed GTAW hot/Cold Wire |

| Main Power Source | EWM Tetrix 552 (500 AMPS) Germany X 4 nos |

| Controller | Programmable Logic control USA made |

| Interface | HMI touch with pendant |

| Rated Operational Voltage | 415 V, 50 Hz |

| Phase | 3 |

| Welding parameter control | 100% programmable |

| Weld Ampère Range | 50-420 AMPS (100% Duty Cycle) |

| Voltage Range | 10-16 volts |

| Wire Feeder Range | 100 to 10000mm /min |

| Travel Speed Range | 1-850 mm/min |

| Cooling type | External refrigerated process Chillers |

| Number of wire feeds | Single /Double (both Compactable) |

| Hot wire Amps | 5-100 AMPS X 4 nos |

| Axis Travel | Servo motors |

| Wire spool Holder | 15 to 250 kg X 4 nos |

| Wire Diameter Range | 1.2 to 1.6 mm (Standard Supply other sizes optional) |

| Maximum Loading Capacity | Diameter 30 INCH, 5 ton |

| Machine Capability | 1-TO-12.6-meter CS pipes, with seam or without seam |

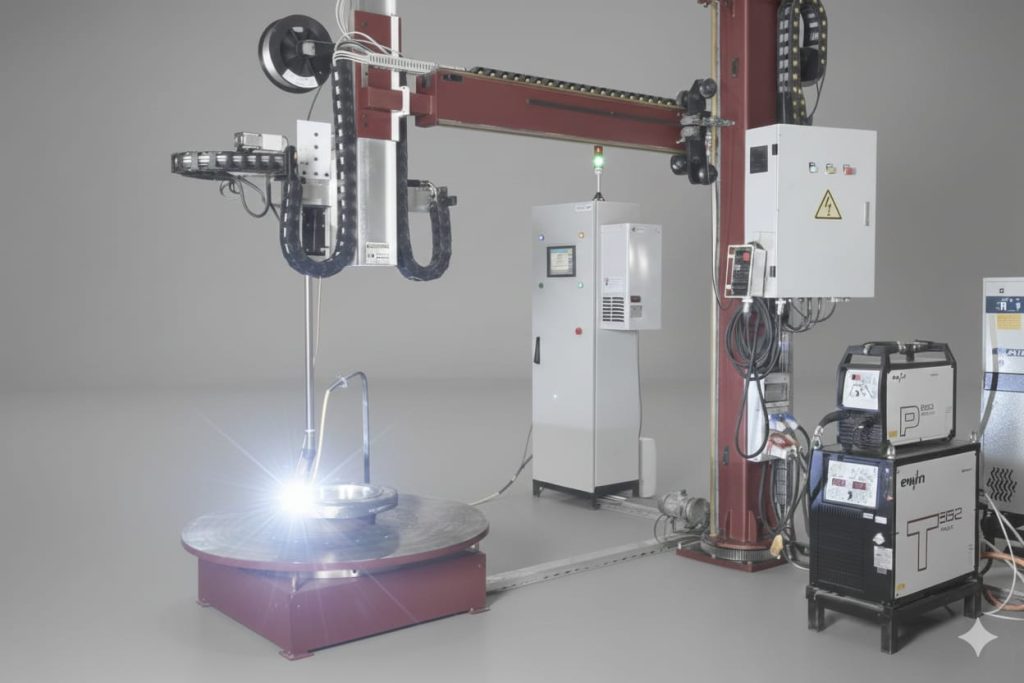

Introduction about Vertical Cladding Machine:

A Vertical Cladding Machine is a highly specialized welding solution designed to apply protective or wear-resistant layers onto vertical surfaces or cylindrical parts held in a vertical position. This machine is essential in industries where components are exposed to extreme wear, corrosion, or heat, requiring surface enhancement to improve performance and lifespan.

Unlike horizontal cladding systems, vertical cladding machines are tailored for upright components such as shafts, valves, and pipes, ensuring accurate metal deposition even on complex geometries. These machines support advanced welding methods such as Plasma Transferred Arc (PTA), TIG, MIG, or SAW, depending on the required application.

Features:

– Vertical Setup: Ideal for cylindrical or long components in upright orientation

– High Precision Welding Torch Movement for uniform cladding thickness

– Supports Multiple Welding Methods – PTA, MIG/MAG, TIG

– Automated CNC Control System for repeatability and ease of use

– Durable Frame & Component Handling System

– Customizable Torch Parameters for different alloys and thickness

Applications:

– Oil & Gas Industry: Valve bodies, drill tools, and connectors

– Power Plants: Shaft cladding, turbine components, and heat exchangers

– Aerospace & Marine: Corrosion-resistant layers for shafts and structural parts

– Heavy Machinery Maintenance: Wear part restoration

– Chemical & Petrochemical: Equipment exposed to corrosive materials

Technical Parameters:

| Type | Vertical compact cladding machine |

| Model No | VCS-1T-2W-H |

| Process | Pulsed GTAW hot/Cold Wire |

| Main Power Source | EWM Tetrix 552 (500 AMPS) Germany |

| Controller | Programmable Logic control USA made |

| Interface | HMI touch with pendant |

| Rated Operational Voltage | 415 V, 50 Hz |

| Phase | 3 |

| Welding parameter control | 100% programmable |

| Weld Ampère Range | 50-420 AMPS (100% Duty Cycle) |

| Voltage Range | 10-16 volts |

| Wire Feeder Range | 100 to 10000mm /min |

| Travel Speed Range | 1-850 mm/min |

| Cooling type | External refrigerated process Chillers |

| Number of wire feeds | Single /Double (both Compactable) |

| Hot wire Amps | 5-100 AMPS |

| Axis Travel | Servo motors |

| Wire spool Holder | 15 to 250 kg |

| Wire Diameter Range | 1.2 to 1.6 mm (Standard Supply other sizes optional) |

| Maximum Loading Capacity | Diameter 1250 mm, 4 ton |

| Machine Capability | Fittings, Flanges, Bends, Valve Bodies ETC |