Introduction on Air compressor:

An air compressor machine is a device that converts power (from electric motors, diesel engines, or gasoline engines) into potential energy stored in pressurized air. The machine compresses atmospheric air and stores it in a tank for various uses — from powering pneumatic tools to controlling industrial processes. Air compressors are indispensable across multiple industries due to their versatility, efficiency, and ability to deliver clean, dry compressed air on demand.

Air compressors are classified in various ways — by pressure rating, displacement mechanism (reciprocating, rotary screw, centrifugal), lubrication method (oil‑lubricated or oil‑free), and mobility (stationary or portable). Each type serves distinct applications, from light workshop use to heavy industrial production lines.

The most basic function of any air compressor is to draw in air, compress it, and deliver it at a higher pressure through hoses or pipes to operate machinery, tools, or processes that require compressed air. When compressed, air becomes a reliable energy source for tools like impact wrenches, paint sprayers, nail guns, pneumatic drills, grinders, blow guns, and more.

Air compressors are among the most versatile power sources available. They power a wide range of pneumatic tools, such as:

– Impact wrenches

– Air ratchets

– Spray guns

– Sandblasters

– Drills

– Grinders

– Nailers and staplers

– Pressure washers

This flexibility makes them suitable for automotive shops, construction sites, fabricators, and manufacturing lines alike.

Features:

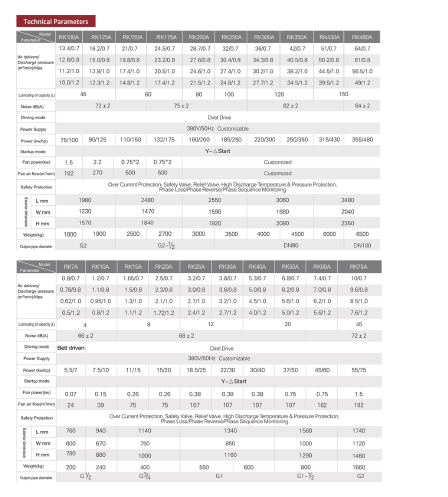

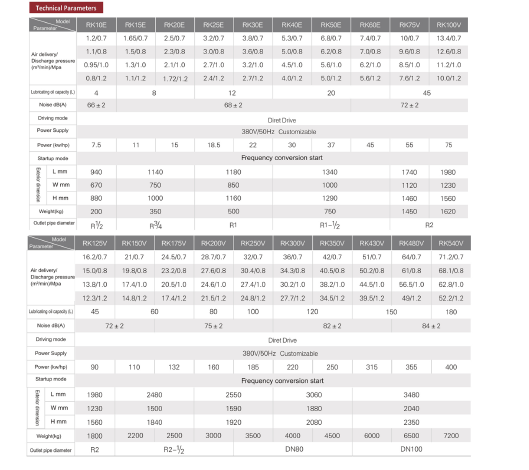

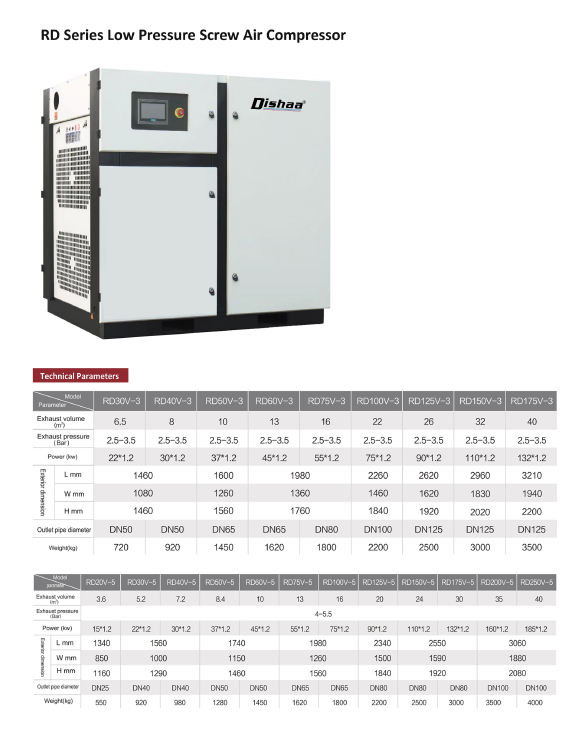

Compressor Type (Mechanism)

Reciprocating (Piston) Compressors

– Uses pistons and cylinders.

– Ideal for intermittent use, lower capacities.

– Common in workshops and small industrial setups.

Power Source

Air compressors can be powered by:

– Electric motors (most common in shops and factories)

– Diesel engines (portable, for construction sites)

– Gasoline engines (for remote or off‑grid applications)

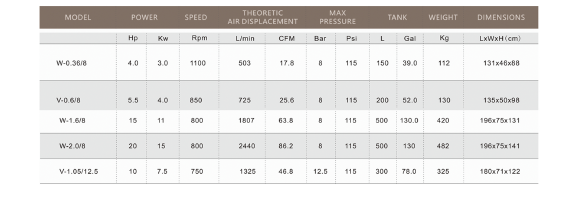

Pressurized Air Delivery (CFM & PSI)

Two main measures define compressor output:

– CFM (Cubic Feet per Minute) — volume of air delivered

– PSI (Pounds per Square Inch) — air pressure level

Tank Size and Storage Capacity

Compressor tanks store air to meet peak demand without overworking the compressor. Larger tanks mean:

– Smoother pressure delivery

– Less frequent cycling

– Better performance for intermittent high‑demand tools

Oil‑Lubricated vs. Oil‑Free

Oil‑Lubricated Compressors

– Durable, quieter, and better for heavy use

– Require oil changes and maintenance

Oil‑Free Compressors

– Lower maintenance, cleaner air

– Ideal for food, medical, and clean environments

Benefits:

Increased Productivity

Compressed air tools often outperform electric equivalents in:

– Speed

– Torque

– Reliability

This boosts overall productivity.

Energy Efficiency

Modern compressors with VSD or pressure controls match output to demand — saving energy and reducing electricity costs.

Longer Tool Life

Pneumatic tools tend to have fewer moving parts and are less affected by heat than electric or hydraulic equivalents — extending tool life.

Clean Operation

Oil‑free systems provide contaminant‑free air — essential for food, medical, and paint applications.

Scalability

Compressed air systems scale from small workshops to large manufacturing plants — supporting multiple users and tools simultaneously.

Lower Maintenance Costs

With proper filtration and routine maintenance, compressors operate reliably and require minimal service.

Safety and Reliability

Pneumatic systems are less prone to electrical hazards and sparks — improving safety in many industrial environments.

Improved Process Control

Compressed air offers precise and responsive control for pneumatic actuators and automated systems — essential in modern manufacturing.

Cleaner Work Environment

Moisture separators and air dryers ensure dry air — reducing corrosion and protecting tools and equipment.

Enhanced Tool Performance

Air‑powered tools deliver consistent torque and power — improving performance for heavy‑duty applications.

Limitations:

Initial Investment and Setup Cost

Good‑quality compressors and associated piping or filtration systems represent a significant upfront expense.

Noise Levels

Compressors can produce high noise, requiring acoustic treatment or enclosed compressor rooms in workshops.

Moisture and Drainage Issues

Without proper air drying and drainage, moisture can build up, causing corrosion or tool damage.

Maintenance Requirements

Regular servicing (filters, oil changes, belts, drains) is required to prevent performance loss.

Heat Generation

Compressors produce heat — which may require ventilation systems or heat recovery mechanisms.

Space Requirements

Large compressors and tanks need floor space and proper ventilation in shop layouts.

Pressure Drop Over Distance

Longer air lines can cause pressure drops — requiring careful design and pressure regulators.

Dependency on Power Supply

Electric models depend on a stable power supply, while engine‑powered units need fuel and engine maintenance.