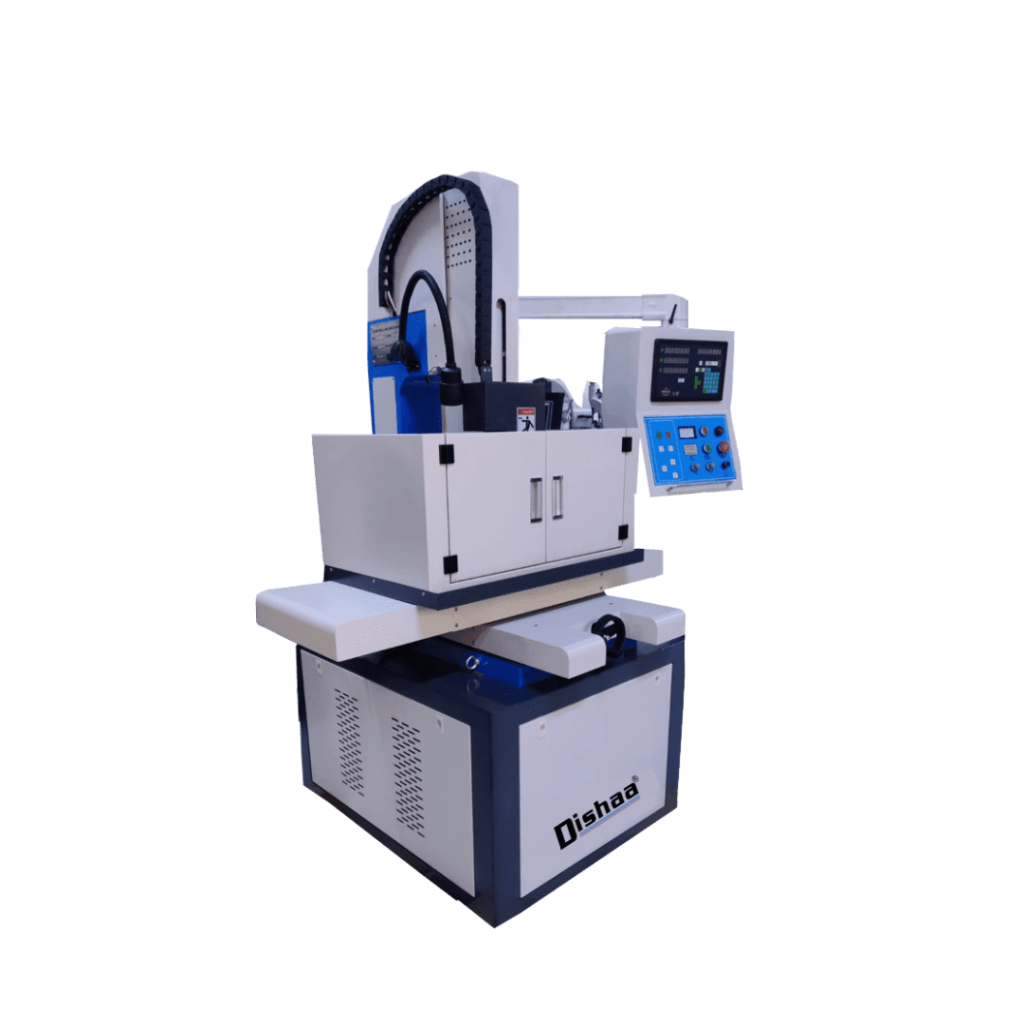

EDM DRILLING

Introduction:

EDM (Electrical Discharge Machining) Drilling is a highly precise and non-conventional machining process used to drill micro and deep holes in electrically conductive materials. Unlike traditional drilling methods that rely on physical cutting tools, EDM drilling uses controlled electrical discharges or sparks to erode the material. This makes it ideal for materials that are hard to machine with conventional methods, such as hardened steel, titanium, carbide, and Inconel.

The process is widely used in aerospace, automotive, tool & die, defense, and medical industries, where high precision and clean hole quality are critical. EDM Drilling Machines, also known as hole popper or spark eroding machines, are capable of producing holes with diameters as small as 0.3 mm and depths of over 300 mm, depending on the application.

How EDM Drilling Works (Technical Overview):

EDM Drilling uses a rotating tubular electrode, typically made of brass or copper, and a high-frequency electrical current to erode material from a conductive workpiece. A dielectric fluid (usually deionized water) is pumped through the hollow electrode, flushing away debris while cooling the work area.

– Spark Discharge: A series of tiny sparks jump the gap between the electrode and the workpiece.

– Controlled Erosion: Each spark removes a small amount of material in a controlled manner.

– No Mechanical Force: This process is ideal for delicate or thin materials as it involves no physical contact.

Maintenance Tips for EDM Drilling Machines:

1. Regular dielectric fluid replacement to avoid contamination.

2. Monitor electrode wear and replace as needed.

3. Clean debris and flush system after long drilling sessions.

4. Calibrate CNC systems periodically for precision.

5. Keep machine environment dust-free to ensure smooth performance.

Features:

Perfect for post-heat-treatment machining where traditional methods fail.

- Fast processing speed and low consumption.

- Auto deep control for blind hole

- Can drill on oblique and curved surface directly

- Can use city water as coolant, low cost and no pollution (Pure water is better)

Importance of EDM Drilling in Modern Manufacturing:

- EDM drilling is crucial for industries dealing with ultra-hard materials. It simplifies the process of creating holes in metals like carbide and titanium that are otherwise too tough for standard machining.

- In the aerospace sector, small cooling holes in turbine blades and precision fuel system components are created using EDM drilling. These components must withstand high temperatures and pressures, requiring precision holes.

- From surgical drills to tiny nozzles in medical devices, EDM drilling provides unmatched accuracy and quality without damaging the materials.

- The process produces very little heat-affected zones compared to laser machine, making it ideal where thermal integrity of the material must be preserved.

- EDM creates burr-free holes, which is a significant advantage over conventional drilling that often requires secondary deburring processes.

Technical Parameters:

| Model | 703.30 | 703.40 | 703.50 | 703.63 | 703.80 |

|---|---|---|---|---|---|

| Working table size (mm) | 320×440 | 540×780 | 650×1000 | 750×1100 | 980×1350 |

| Stroke X/Y (mm) | 300×400 | 400×500 | 500×630 | 630×800 | 800×1000 |

| Electrode diameter (mm) | φ0.2-φ3.0 | φ0.2-φ3.0 | φ0.2-φ3.0 | φ0.2-φ3.0 | φ0.2-φ3.0 |

| Working stroke Z axis (mm) | 300 | 300 | 400 | 500 | 500 |

| Spindle stroke W axis (mm) | 300 | 400 | 500 | 500 | 500 |

| Distance between working table & guider(mm) | 300 | 350 | 400 | 500 | 500 |

| Power (V/Hz) | single phase 220V 3 Phase 220,230,380,415V /50, 60HZ | ||||

| Max.working current (A) | 30 | 30 | 30 | 30 | 30 |

| Capacity of working fluid (L) | 25 | 25 | 25 | 25 | 25 |

| Max.pressure of working fluid (MPa) | 7 | 7 | 7 | 7 | 7 |

| Dimension (L×W×H) (mm) | 1060×750×1700 | 1600×1300×1800 | 1800×1500×1900 | 2100×1700×2000 | 2400×1900×2000 |

| Weight (kg) | 600 | 1100 | 1600 | 2200 | 2800 |