NC LATHE MACHINE

Introduction:

Unlike conventional lathes, NC lathes automate the control of the cutting tool and workpiece through pre-programmed instructions, reducing manual intervention and human error. This automation makes NC lathes ideal for batch production, high-precision components, and repetitive industrial operations.A Numerical Control (NC) Lathe Machine is an advanced metalworking tool used for precision turning, threading, drilling, and shaping of cylindrical workpieces. It represents a significant evolution from conventional lathe machines by incorporating numerical control technology, allowing operations to be automated based on pre-programmed commands. The NC lathe machine is widely used in modern manufacturing industries such as automotive, aerospace, electronics, and mechanical engineering, where accuracy, repeatability, and efficiency are critical.Unlike conventional lathes, NC lathes automate the control of the cutting tool and workpiece through pre-programmed instructions, reducing manual intervention and human error. This automation makes NC lathes ideal for batch production, high-precision components, and repetitive industrial operations.

Unlike traditional lathes, which require manual operation and adjustment by skilled operators, an NC lathe machine can perform complex operations with minimal human intervention. The machine reads numerical codes from punched tapes, magnetic tapes, or digital programs to control the movement of the cutting tool along the X and Z axes. This automation ensures high precision, reduces human error, and significantly increases production speed, making NC lathes ideal for batch production and repetitive machining tasks.

Working Principle of an NC Lathe Machine:

The NC lathe machine operates on the principle of controlled movement of the cutting tool and workpiece based on pre-defined numerical instructions. The workpiece is mounted on a rotating spindle, while the cutting tool moves linearly along programmed paths. The machine’s motion, including speed, feed, and depth of cut, is controlled electronically, allowing for highly accurate shaping of metals and alloys. Modern NC lathes often include digital readouts and microprocessor-based controllers to improve programming flexibility and precision.

The machine can perform multiple operations such as turning, tapering, grooving, threading, and drilling in a single setup. Automated tool changers and tool holders enhance productivity, enabling the machine to switch between different cutting tools efficiently. This reduces downtime and improves the overall output quality in industrial applications.

Applications of NC Lathe Machine:

- Machining cylindrical components with high precision for automotive engines and shafts.

- Manufacturing aerospace components requiring tight tolerances.

- Producing mechanical parts for industrial equipment and machinery.

- Thread cutting, grooving, and shaping of metal rods and pipes.

- Small and large-scale batch production requiring consistency and repeatability.

Adventages:

- High precision and repeatability in machining operations.

- Reduced reliance on manual labor and operator skill.

- Ability to perform multiple complex operations in a single setup.

- Faster production and shorter lead times for batch manufacturing.

- Minimizes human error and improves quality control.

- Flexible programming allows for easy adaptation to different workpieces.

Features:

- Higher stability one-piece machine bed

- 3-gear spindle speed, step-less in gear

- Higher rigidity base

- Wider slide carriage

- Integrated automatic lubrication system

The NC Lathe Machine is a cornerstone of modern manufacturing, offering high precision, automation, and efficiency. Its ability to perform multiple turning operations with minimal human intervention makes it indispensable for industries that demand quality and productivity. With its robust construction, digital control systems, and versatility, the NC lathe machine ensures long-term reliability, reduced production errors, and faster turnaround times, making it a valuable investment for any metalworking or industrial workshop.

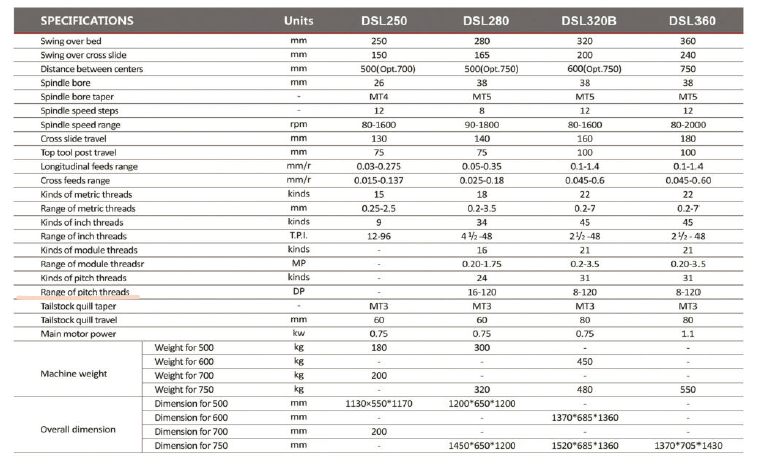

Technical Parameters: