PROFILE BENDING

Introduction:

A Profile Bending Machine is a critical industrial device designed for bending metal profiles — including circular pipes, square tubes, angles, channels, I‑beams, H‑sections, and flat bars — into precise curved shapes. In modern fabrication and manufacturing environments, the need to transform linear metal stock into accurate curves and arcs is increasingly common across sectors such as architecture, construction, aerospace, shipbuilding, automotive, and infrastructure projects.

Profile bending is not a process that can easily be achieved by simple manual force or traditional metalworking tools. The complexity arises from maintaining geometric integrity, structural strength, and accurate curvature throughout the workpiece. In high‑demand industrial fabrication, accuracy is not an afterthought — it’s a necessity. To meet this challenge, profile bending machines employ robust roll systems, hydraulic drives, CNC controls, and heavy‑duty frames built to withstand repetitive stress and high tonnage forces.

Whether you’re running a specialized metal fabrication workshop or operating a large industrial plant, understanding the capabilities and intricacies of profile bending machines is crucial. This article will dive deep into why these machines are indispensable, what features to look for, how they are used, and the unique benefits and limitations of integrating them into your operations.

Why Use a Profile Bending Machine?

Using a profile bending machine goes far beyond the ability to simply curve metal. It’s about achieving precision, efficiency, safety, and repeatability that traditional methods cannot deliver. Below are key reasons industries prefer profile bending machines over manual or semi‑automated solutions:

Precision and Accuracy

Profile bending machines are engineered to bend metal with precision that meets industrial tolerances. For many applications, especially in construction and engineering, even a millimeter’s deviation can lead to structural weakness or aesthetic flaws. The machine’s hydraulic or servo‑controlled systems ensure consistent bending radius, angle, and profile orientation.

Capability to Bend Various Materials

Unlike manual bending tools that struggle with thicker or harder metals, profile bending machines can handle a wide range of materials:

– Mild steel

– Stainless steel

– Aluminum alloys

– Copper and brass

– High‑strength structural profiles

Efficiency and Time Savings

Manual bending processes are labor‑intensive and time‑consuming. Profile bending machines automate the bending process, accelerating production cycles and freeing operators to focus on other tasks.

Safety

Manual bending involves significant physical strain and risk. Profile bending machines are designed with safety in mind, featuring guarding, automated controls, and ergonomic setups that minimize operator exposure to moving parts and high force zones.

Features:

Heavy‑Duty Frame and Robust Construction

A high‑quality profile bender starts with a rigid frame built from thick steel plates and welded for maximum strength. This stability ensures the machine can withstand repeated bending cycles without deformation or vibration — crucial for precision.

Multiple High‑Strength Rollers

Most machines use a three‑roller design (sometimes four) with adjustable positions:

– Top roller applies the bending force

– Two bottom rollers support the profile and allow it to curve

– Some advanced models include independent rear roller movement for variable bending

Hydraulic Drive System

Hydraulics provide smooth, controllable force. Advantages include:

– Adjustable pressure

– Stable force application

– High load capacity

– Low maintenance

CNC or Computerized Control

Advanced profile bending machines often have CNC control, which allows:

– Programming multiple bends

– Storing bending sequences

– Automatic positioning of rollers

– Precision repeatability

Adjustable Bending Radius and Roller Position

The machine allows the operator to define exactly how much curvature is applied, based on:

– Material thickness

– Desired radius

– Profile cross‑section

Safety Systems

Essential safety features include:

– Emergency stop buttons

– Guarding around moving parts

– Foot pedal operation for safer hands‑free control

Applications:

Construction Industry

Metal structures in modern buildings often include:

– Curved beams

– Arched supports

– Complex framework sections

Infrastructure & Bridges

Steel girders and support arches in bridges require precise curved profiles to ensure even load distribution and aesthetic alignment.

Shipbuilding & Marine Structures

In ships and offshore platforms:

– Curved frames

– Hull stiffeners

– Deck structures

Curvature is essential, and profile bending machines provide consistent results under heavy material loads.

Architectural Metalworking

Curved metal components are popular in artistic facades, stair railings, window frames, and landmark sculptures. Profile bending machines deliver both functional and aesthetic curves.

Oil, Gas & Pipeline Industry

Pipelines often require pre‑bent sections at various angles for terrain adaptation, welding ease, and flow efficiency.

HVAC and Ducting

Complex duct curves improve airflow and reduce fabrication/assembly time in ventilation and AC systems.

Agricultural Equipment

Curved frames and supports are common in farm machinery, trailers, and implements.

Metal Fabrication Workshops

Profile bending machines form the backbone of mid‑ to large‑scale machine shops that produce custom bending jobs for diverse clientele.

Energy & Renewable Structures

Wind turbines, solar panel supports, and structural hardware often require precisely bent metal profiles for optimal performance.

Benefits:

Time & Cost Savings

Automation and efficient bending cycles reduce labor time and cost, particularly in batch production.

Material Versatility

Accommodates a wide variety of metals — from mild steel to high‑strength alloys — and profile shapes.

Reduced Scrap

Accurate bending reduces mistakes and waste, lowering raw material costs.

Increased Throughput

High productivity and repeatability make profile bending machines ideal for commercial fabrication environments.

Safety & Ergonomics

Mechanized bending reduces manual strain and improves workshop safety.

Scalability

From small shops to large factories, machines can be sized and configured to meet production needs.

Improved Structural Performance

Curved profiles maintain structural integrity — important in bridges, buildings, and weight‑bearing assemblies.

Limitations:

Operator Skill Required

Training is essential to set parameters, position workpieces, and interpret bending results, especially for complex profiles.

Material Spring‑Back

Certain metals may spring back slightly after bending. Compensation through programming or experience is required.

Size and Space Requirements

Large profile bending machines need dedicated floor space and structural support in the workshop.

Maintenance Needs

Hydraulic, electronic, and mechanical systems need periodic maintenance to remain accurate.

Not Ideal for Very Thin Materials

Very thin, flexible materials may not produce consistent curvature without special support or machine settings.

Cost of Spare Parts

Rollers, hydraulic components, and control modules have replacement costs that add to lifecycle expenses.

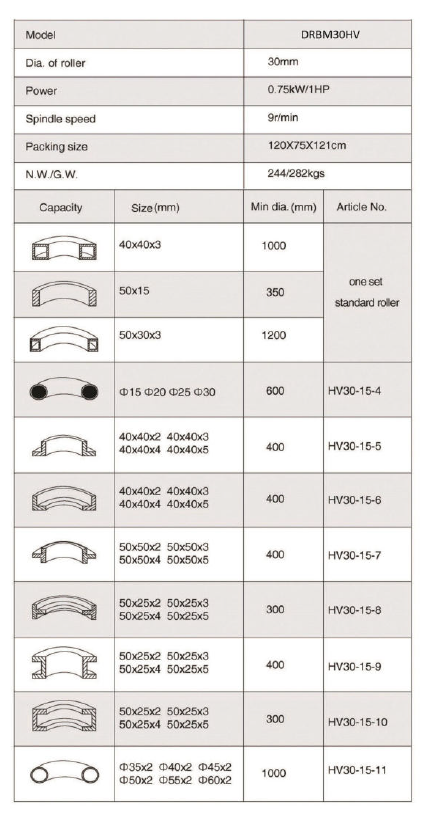

Technical Parameters: