PNEUMATIC PRESS

Introduction:

It is a type of mechanical equipment that uses compressed air to apply force in industrial applications such as punching, pressing, bending, assembling, and forming. Unlike hydraulic presses that use fluid pressure, pneumatic presses operate with air pressure, making them faster and cleaner. These machines are known for their precision, speed, and ease of use, and are widely used in light to medium-duty manufacturing processes.

These machines are especially useful in assembly lines, automotive workshops, metalworking shops, electronic device manufacturing, and plastic forming industries. Pneumatic presses help reduce manual labor, improve product consistency, and enhance operational safety—making them a valuable addition to any modern factory.

What is a Pneumatic Press Machine?

A pneumatic press is a mechanical device that uses compressed air to generate force for pressing, punching, bending, or forming materials. It is a cost-effective and reliable alternative to hydraulic or mechanical presses, especially in applications where moderate force and high-speed operations are required.

Working Principle:

It works by converting air pressure into mechanical force. When compressed air enters the cylinder, it pushes the piston downward, which in turn applies pressure to the die or tool attached, performing the required operation. The speed and force can be adjusted by regulating the air pressure.

Applications:

- Suitable for blanking, punching, forming, bending, stretching and other cold stamping process to achieve.

- Widely used in electrical appliances, vehicles, tractors, mining machinery, hardware tools, machin manufacturing and other industrial areas.

Features:

- Steel plate welded body, stiffness, more stable.

- Dry pneumatic friction clutch-brake, friction machine for semi-metallic materials.

- The imported safe double valve control, quick, safe and reliable

- Mold height realize electric adjustment, digital display control height.

- Slider use rectangle hexahedron extended guide, bronze lining board, high guidance accuracy.

- International famous brand special press control system,

- Automatic feeding device and all kinds of automation equipment

Why Choose Dishaa’s Pneumatic Press?

At Dishaa Machinery & Tools, we provide CE-certified pneumatic presses that are engineered for performance, durability, and safety. Our machines are backed by a 2-year warranty and lifelong technical support. We serve industries across UAE, GCC, and Africa, and have built a solid reputation for our quality, service, and commitment to customer satisfaction.

We offer:

– Free installation & training

– Online & onsite service support

– Ready spare parts availability

– Custom-built solutions based on your industry needs

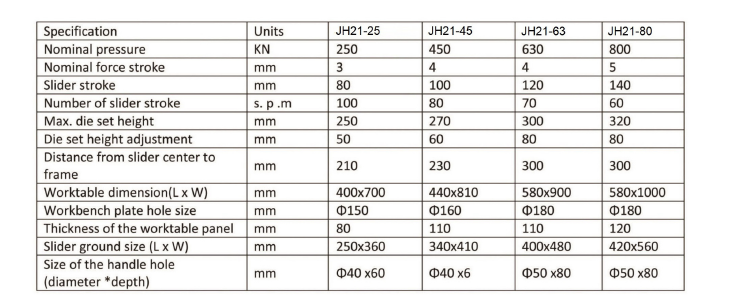

Technical Parameters: